Firearms inventory management is critical to your profitability, but it also has an impact on your customer experience, employee morale and how smoothly your business runs. This is especially true in the highly regulated world of firearms and explosives where regulation, safety, accuracy and customer demands collide in your warehouse or magazine.

I’ve recently written an article on optimizing inventory for all types of distributors and manufacturers, Comprehensive Inventory Analysis for Sales, Economic Order Points, and Strategic Optimization – Business Automation Specialists, but now I would like to specifically address inventory management for firearms manufacturer, importer or wholesaler.

Understand Your Firearms Inventory

Inventory management is key to your business. Whether you have a $10,000, $100,000, $1,000,000, or $10,000,000 to “invest” in inventory, your choices are critical to your success. Your warehouse (or backroom) will never be big enough if you purchase the wrong product. Your margins will never be high enough if you don’t have the right product when the customer wants to buy it.

In addition to understanding your inventory, you must understand your customers’ wants and demographics (income, age, perceived need, region, and taste), current trends and how your products fit into the current trends and customer demographic. You must answer the question, “Why do my customers buy my products?” Is it price, quality, prestige, necessity, esthetics, or something else? I have said for many years, “If you are just like the guy down the street, one or both of you will be out of business in five years”.

Evaluate Your Inventory Flow-Through

One important question for you as a firearms manufacturer, importer or wholesaler is flow-through. It is easy to look at this month’s sales and be impressed, however, this month’s sales generally aren’t going to be in the consumer’s hands for several months. No sale is really a sale until the end user owns it. Otherwise, it is just gathering dust and taking away from next month or next year’s sales. Keep that in mind as you give that big discount to move more guns to a buyer than that buyer has capacity to move to the end user.

Pro Tip – check out NSSF Firearms Retailer Survey or use a service like NASGW SCOPE DLX to check trends and actual flow through based on retailer’s purchases. You might also check out Gun Genius to see what is selling on Gun Broker.

I spoke about being careful at discounting to move guns to someone who couldn’t sell them. Take that same advice when buying your inventory, whether raw materials, firearms or accessories. Which is better, assuming the same retail price. Should you buy 1,000 of one thing with a 75% discount off retail or 50 of 20 things at a 50% discount? Obviously, the answer depends on how many you can move. You will not break even if you buy 1,000 of an item and sell or use 100 during the year; however, if you sell only half of the 20 products you bought, you will break even. And, giving your customers a choice of 20 products makes your success probability much higher. Now, consider how long you will have to hold onto those 900 remaining items and how much warehouse space they will consume versus the 500 of the 20 products.

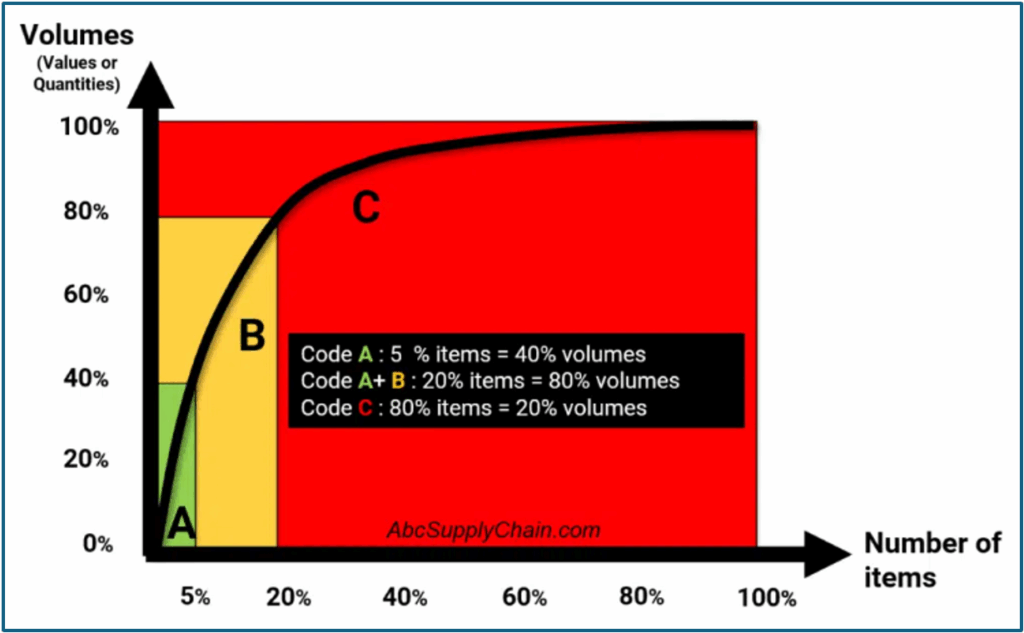

- ABC Analysis – How do you know what to carry if you don’t know what you sell.

- Pareto’s 80/20 rule is a good start. Take approximately 20% of your inventory that produces approximately 80% of your revenue and prioritize those items in your inventory. Consider assigning these items to one person on your team whose responsibility is to make sure you are never out and to get you the best terms (price, minimum order quantity, priority delivery, etc.)

- The next 30% of your firearms inventory may account for 15% of your revenue, but never-the-less it is important to your overall profitability.

- Finally, the last 50% of your inventory makes up 5% or less of your revenue. Consider which of these products you really want to carry and jettison the rest. Make room for “A” products and minimize the frustration of too many SKUs to manage effectively.

- Firearms Inventory Turnover – you can use the 80/20 rule here, too. However, this focuses on how often you sell the item. When you combine this with Tip #1, you’ve got a solid framework for figuring out what really needs your attention. This is a useful article to help you do this: 11 Effective Strategies To Optimize Inventory, Reduce Costs, And Improve Supply Chain Efficiency | AbcSupplyChain

- Determine your Approved Stock List – recognize that you cannot be everything to everybody. What is it that you want to be the best at supplying? Too many of us want to supply everything to everyone. Jon Schreibfeder (Developing and Maintaining Your Approved Stock List – Effective Inventory Management) makes the point that you should have a formal procedure for introducing new products (and, I think, a procedure for maintaining all items in inventory). He says you need to answer questions such as: Who is going to buy the product? Why are they going to buy from us? What do we estimate we can sell of the product during the first six months? How will this product affect the sales of our other products?… The biggest factor to ungoverned growth is an undisciplined approach to adding new firearms products.

- Drop Shipping – this is a great time to include drop shipping. Many vendors will take those items in the C range and drop ship them to your customer for you. (You can also do this for your reselling customers.) You may take a lower margin, but you don’t lose the sale, you don’t take up the warehouse space, you don’t have to manage that item and you still made the sale. (Better yet, with an ERP like Microsoft Business Central, you can automate the Purchase Order process to minimize your administrative load. Learn more here: Make drop shipments – Business Central | Microsoft Learn)

- Collaborate with Customers – talk to your customers to better understand their future buying habits. What would they buy from you if you guaranteed to have it in stock? What do they see for future demand? How can you minimize their efforts in managing their inventory? Get their forecast.

- Use your ERP system – Well, you know I would say this – we sell Microsoft Dynamics 365 Business Central ERP. In fact, we have combined Business Central with our proprietary ATF compliance software to create a firearms manufacturing ERP and a firearms ERP for distributors. But seriously, your ERP can provide a great tool to minimize the time it takes to manage your inventory. Your ERP probably already has built-in tools to help you know what to order and when. But it won’t work without your input. It doesn’t know your vendors part numbers, minimum orders, order multiples and so on. You do (or should). Take the forecast you found in Step 4 and put it into your ERP. Put it into your ERP and use the planning tools in it to maximize the data that it can supply you. Simple planning of purchase items, using the Requisition Worksheet – Dynamics 365 Business Central

- Consignment Inventory – consignment inventory can save you time, money and warehouse space and can work with your customers and vendors. Yes, it will require a little monitoring, but a monthly billing without weekly purchase orders and invoices can also save administrative and freight costs. Do you sell items that you can stock in your customer’s warehouse to save you warehouse space and they can use in their production or sales? Do you have vendors who will stock their product in your warehouse to save you inventory dollars?

- Alternate Part Numbers – Do you have alternative items for items that you don’t have on your Approved Stock List. For example, you use a 1 3/8” screw in an assembly (or your customer wants to) – do you list alternate part numbers for a 1 ¼” and a 1 ½” screw on the 1 3/8” screw as alternatives. Or someone asks for a 20 round AR magazine, and you carry 15, 25 and 30 round magazines. Offer them an alternative. This cuts your SKU count by 25% for this item. Many customers are willing to accept a substitute.

- Regular Audits and Stock Reviews – is your physical inventory in sync with your ERP? Check your A inventory monthly, your B inventory quarterly or semi-annually and your C inventory annually. This will increase your firearms inventory accuracy and minimize stock-outs. It is also a great time to move out the dead inventory and reduce your SKU count, accomplishing three things at once – financial accuracy, physical accuracy and pruning your Approved Stock List.

- Cross Docking – this isn’t for everyone, but, if you have customers ordering large quantities of a product, but less than a truckload, consider filling the truck, unloading at your location and move the customer order from receiving to shipping without putting the product away. You may save money on shipping and certainly will on handling costs. Cross-Docking: Definition, benefits & best practices | Maersk

- Bulk Shipping – coupling this with Cross Docking can be an effective strategy to take advantage of full-truck discounts for shipping and product costs. Don’t overbuy to get a big discount because it can cost you more for handling, damage and obsolete products than you save. Consider this and cross docking for high volume and products that require a lot of storage space.

- Automate Data Collection – Realtime inventory, accuracy and visibility increase when your warehouse uses handheld computers, scan barcodes to pick and put-away items and the system tells the worker where to find a product. Commonly called Warehouse Management Software (WMS), this combination of processes and hardware can improve your customer service by reducing mis-shipments, letting customer service know when a product gets out of stock in real-time and reduce the walk-time, allowing the worker to be more productive. This is not a magic wand and will require a great deal of discipline in your warehouse, but the benefits can far outweigh the cost. The 5 Key Benefits of a Warehouse Management System | GoRamp

- Reslot your firearms inventory – take a little time to reorganize your inventory, consolidating your high movers close to your packing and shipping area. Do this carefully or you will wind up significant congestion in a few aisles and bins. However, with planning, you can reduce travel time significantly.

- Consider how you pick – batch picking (consolidating multiple orders together) can speed up your picking process – use it if you have lots of similar orders (IE special sale or promotion). Wave picking groups orders based on certain criteria (IE next day, UPS, FedEx, LTL, etc.) to allow flexibility of order fulfilment. Wave Picking Vs Batch Picking: Which Is The Best Choice?

- Put your best, most consistent person(s) in put-away – one mistake in put-away can result in dozens of mistakes or missing product when picking. Consistency and accuracy during put-away will reduce errors and time-spent throughout your warehouse process.

Like most things in life – you can’t fix or improve everything at once. My advice is pick a 50% issue – one that causes frequent problems – and work on improving that process.

We Can Help You Manage Your Firearms Inventory

The time you save from reducing the error rate in that problem area will free up time and energy to work on more difficult issues. We’ve helped companies streamline their firearms inventory and thrive in volatile markets. One client told me, “We would never have survived the COVID boom without your team and Business Central.” That same customer said yesterday, “We did a complete Firearm Reconciliation of more than 9,000 guns in less than 2 1/2 hours.” You can watch our client testimony in these videos. Let’s talk about how we can help you, too.